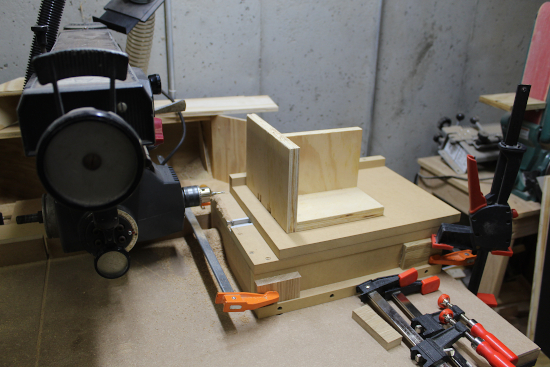

The mortising table I built for my Radial Arm Saw is working out way better than I had hoped. I’m making a batch of 5 identical products that require a combination of 50 slots and mortises of different widths and depths. Some had to be cut on the face of the boards so I mounted a support (shown in the above picture) that allowed me to clamp my boards vertically. The slots, like the mortises, stop short of the board edges. With the board mounted securely to the sliding table, plunge cutting with a spiral carbide bit is simple and accurate. No chance of the board getting squirrely. The setup was a breeze. I made the cuts faster, easier, and more accurately than I could have with any other tool in my shop.

When I brought this rusty old RAS home to restore, I wasn’t sure how much use I’d get out of it. I had hoped to add some redundancy to my shop. It always seems like as soon as I get my table saw setup for miters or dados, I’ll realize I need more boards cut than I have, and I’ll have to set it back for straight cuts. But now that the RAS is up and running, it’s quickly becoming an indispensable tool adding redundancy and capability that I didn’t have.

Be First to Comment