I tested my freshly reassembled vintage 1974 Sears Craftsman Radial Arm Saw today by making a sawdust collection box, and a shelf to go underneath. The saw performed well on all cuts: crosscuts, rips, and miters. After checking the sawdust dispersal pattern, I’ve decided to reposition the box a few inches to the left. I’ve also decided to square the sides and install a top. The dust is hitting the box back, shooting up and out past the mitered left side. I’m waiting on some dust collector fittings to arrive. Once I have it connected to the system, I’m hoping the downdraft will help contain some of the bounce out.

I put on a blade I had retired from my table saw to do the setup and testing. Once I get a new blade, I plan to design and build a project that will use all, or most of this saw’s capabilities. I have a drill chuck on the way that should give me drilling, routing, and milling capabilities. I suppose I could also throw a sanding spindle in the chuck. Maybe I’ll add some curves that require spindle sanding. Not sure how far I want to take the project. I’ll probably start with milled lumber and use a palm sander for the finish sanding.

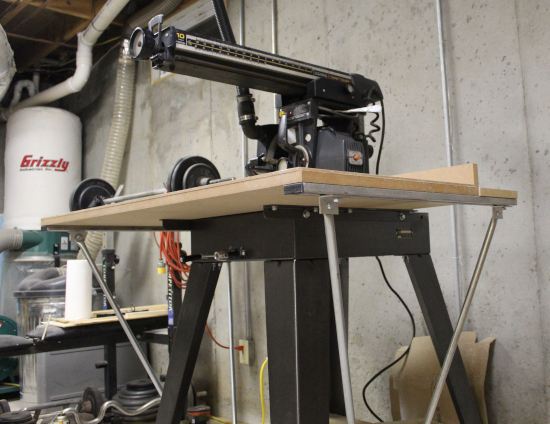

I put a 48″ wide MDF table on the saw to give me plenty of work surface. The original table was smaller, maybe 30″ or 36″. Because of the extra width, the edges were drooping, so I added an adjustable table leveler to each side. This setup worked surprisingly well, allowing me to get the table dead flat, square to the blade, and parallel to the arm all the way across.

Be First to Comment